News

3-D Printing Human Tissue

Undergraduates in Assistant Professor of Physics Cody Crosby’s labs are learning how to “print” viable human tissues and organs.

July 15, 2021

July 15, 2021

Open gallery

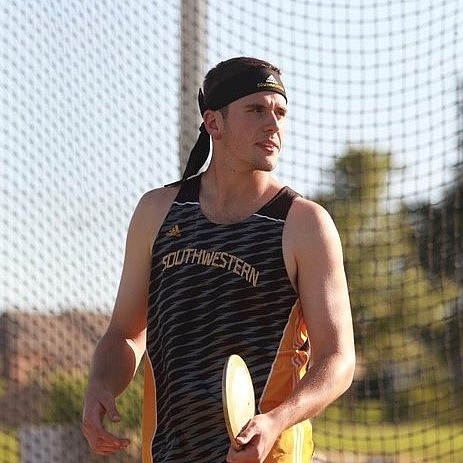

This summer, Assistant Professor of Physics Cody Crosby and three of his students—biology and business double major Andrew Vergote ’21, physics major Katie Rosencrantz ’22, and physics major Jonathan Smart ’23—are collaborating on an innovative research project that may change how we manufacture human tissue.

To engineer human tissue in the laboratory, Crosby explains, cells are typically isolated, expanded, seeded, and incubated in a medium that’s intended to aid the final tissue’s growth and maturation. However, in the last five years, researchers have increasingly recognized that engineered tissue fails to mimic the physiological complexity and lacks the necessary blood vessels of human tissue. Bioprinting, a process that integrates current 3-D printing technology with the latest developments in bioengineering to “print” viable tissues and organs, may be able to overcome these limitations.

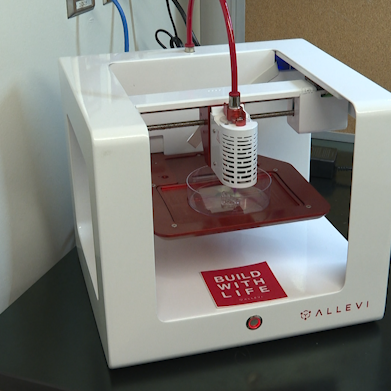

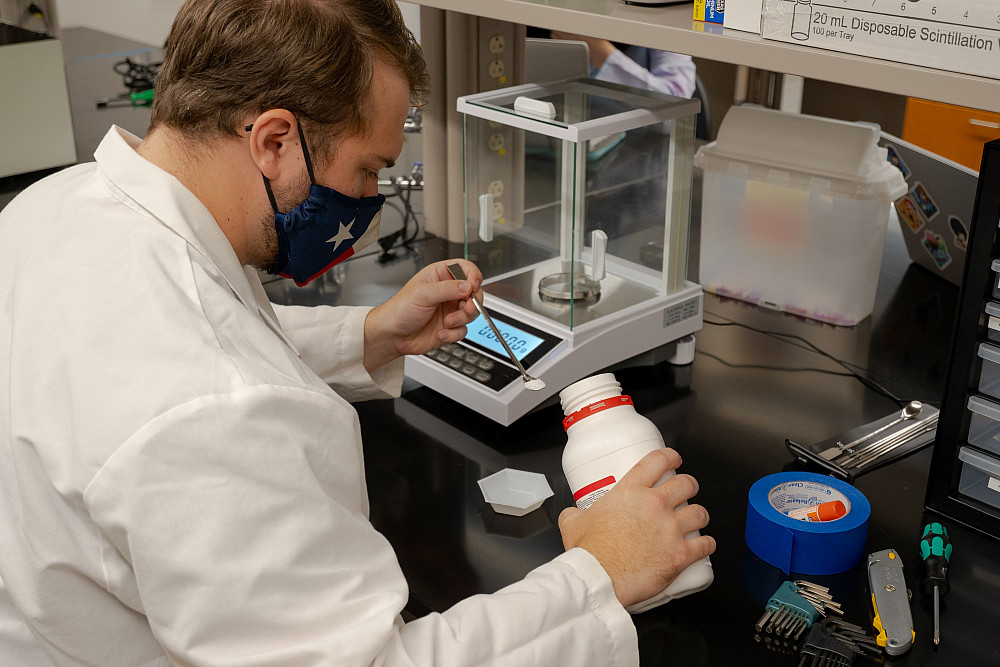

Crosby’s lab endeavors to build low-cost bioprinters and synthesize novel bioinks to further the development of bioprinting technology. Bioinks are mostly composed of cells and other materials that are combined and used to 3-D print live tissue. Vergote is synthesizing a collagen bioink derived from rat-tail tendons and a semisynthetic bioink known as methacrylated gelatin, or GelMA. Smart is performing calibration tests with the 3-D bioprinters and strength tests on the various bioinks the team has created. Rosenkrantz, meanwhile, is testing and evaluating the most recently published open-source bioprinting platform from the laboratory of Adam Feinberg, a bioengineering professor at Carnegie Mellon University.

“The most difficult aspect of this project is working with our TissueScribe bioprinter as the software and hardware associated with the process has to be adopted for use in bioprinting,” Smart shares. The bioprinter’s base software and hardware were originally developed to work with polylactic acid (PLA), the plastic filament most commonly used in traditional 3-D printing. So he and his labmates put significant effort into adapting the process from “extruding [PLA] filament to extruding viscous, soft materials from a syringe.”

Bioprinting human tissue offers an exciting solution to multiple challenges in human health. For example, the population of living and deceased organ donors has been shrinking during the past 15 years, but bioprinting may decrease or eventually eliminate the need for organ donors by generating tissues and organs from the patient’s own cells. Such innovation could therefore also mitigate the risk of rejection—that is, when a recipient’s immune system attacks a transplanted tissue or organ, which can cause damage to the transplant and endanger the life of the patient. Another application of bioprinting is in the development of new drugs: companies could test new pharmaceuticals on engineered human tissue rather than on animals, saving money and time by implementing a more efficient and cruelty-free development process.

Smart, who is also minoring in mathematics, says that Crosby “is a wonderful mentor” and that collaborating with his physics professor “has been an absolute pleasure,” especially considering that the junior is new to lab work. Smart hopes to pursue his master’s degree in an astronomy research lab in Sweden after graduation and will be applying what he’s learned this summer to that work. “I enjoy the aha moments that come with doing work with these printers,” he shares. “Research is a very slow grind, so the moments when I make a breakthrough working on this project really get me excited!”

Crosby expresses gratitude for his undergraduate research collaborators. “I am thankful to have joined the faculty at Southwestern University because I enjoy working in the laboratory alongside my students,” he says. “Their work this summer was exemplary, and I hope to continue to build upon it in the years to come.”